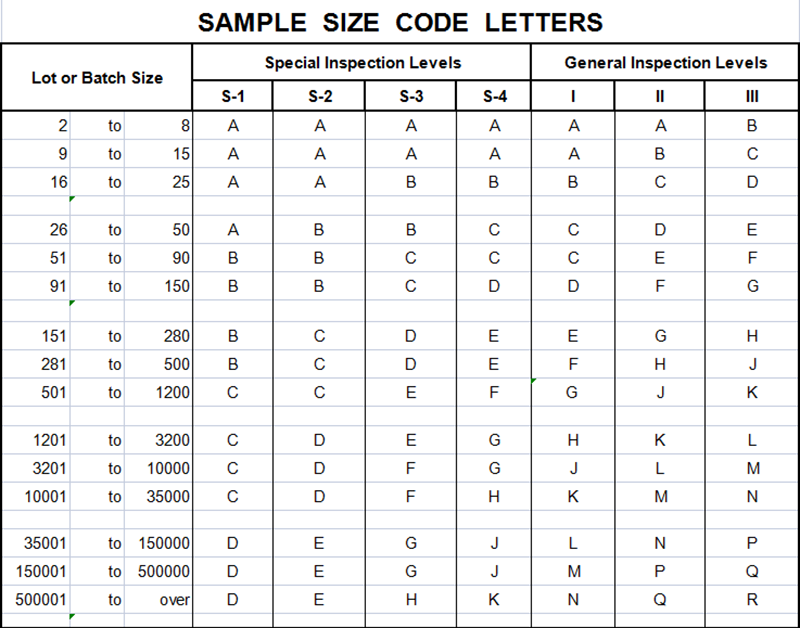

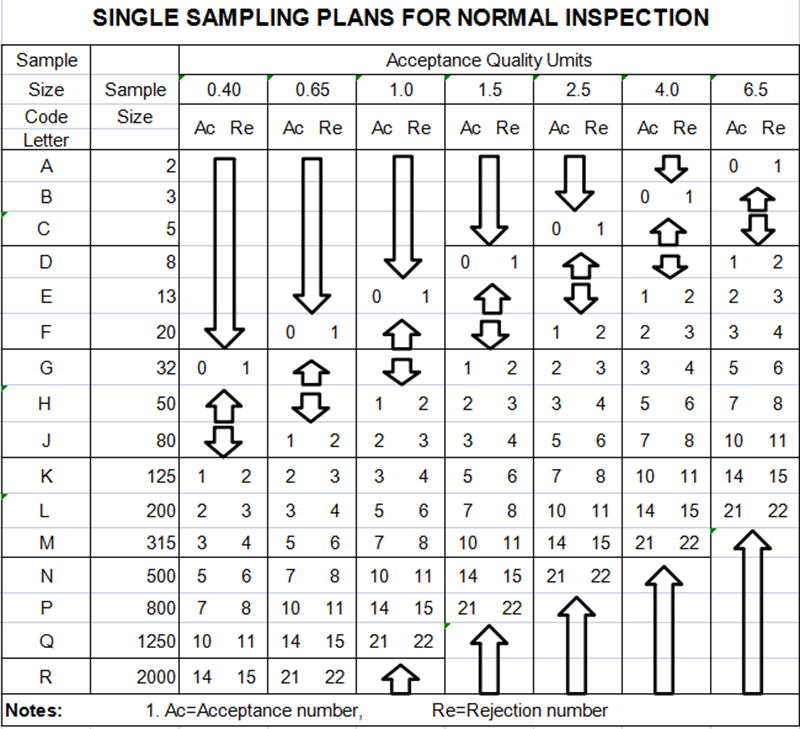

Factory Quality Checking AQL2.5-4.0

For each bulk production, when production team got the order sheet, they can start arranging bulk raw materials sourcing from different factories, e.g. fabric/lining/padding/accessories/labels/hangtag/polybag/carton factories.

When materials arrived, firstly do cutting work, after cutted, then start sewing, every line need to sew straightly, evenly, equally for needles, somewhere need double sewing, somewhere need hidden sewing line so that it would be more solid to be used in reality.

When the bag was finished, QC team would check from pattern, fabric/accessories, workmanship, packing, labels/hangtag, marks for cartons, every detail we need to check one by one step, to ensure the bag in good condition to be shipped, if meet somewhere were sewed wrongly, we need to revise soon, so that NOT give customers trouble in oversea warehouse.

Before packing, our QC team again checked each bag workmanship, from inside to outside, every detail, every zipper whatever bigger or smaller pocket zipper, we need to open/close to see whether something wrong with the bag, especially the hanging loop, we pull whether drop off to test whether durable.

Our shipped bag quality is strictly based on AQL2.5-4.0 ( pls find below), to be frank, all bags are in superior condition, and every customer is satisfied for each shipment, so business is simple for us, we did good work and customers do good selling, it’s a good circle to cooperate yearly on long term basis.

So, every order, when bags arrived at oversea destination warehouse and satisfied to be distributed, all customers can earn money as planned to import, we let business to be simple and trustful in the worldwide countries.

In one word, quality is the cornerstone of long cooperation, we have been doing for ten more years, welcome the coming customers for simple cooperation in the near future.

Post time: Mar-22-2022