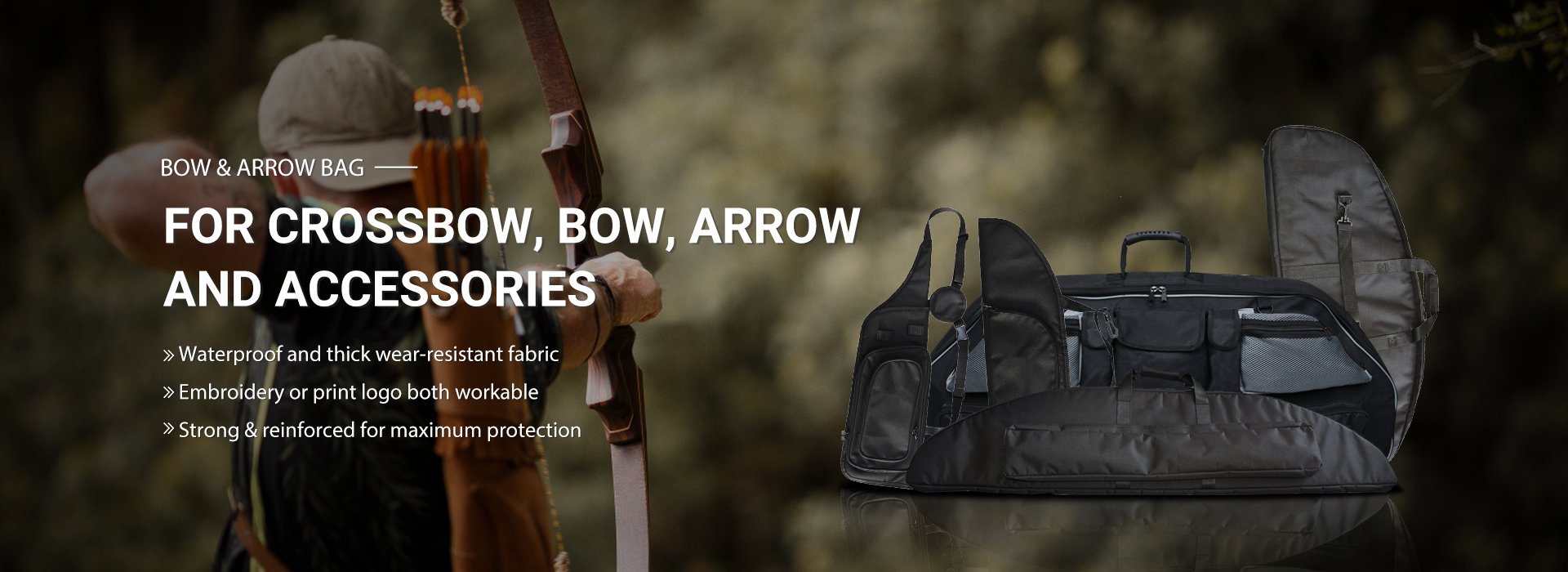

Gun Bag Pattern and Cutting

Today, we share a pattern topic, each bag sample, need to make a pattern, then samples would come out before our eyes, now for pattern, below 4 points are to be paid more attention in the public.

1.1stly, when making a bag pattern, whatever styles or designs, we need to find out that what kind of materials are used to make this model. Because if we design and make a bag and don’t know what material it is made of, how can we talk about the special proofing of bags? So we should know that different materials have different methods when designing, or some raw materials are not suitable for making bags with certain structures.

2.2ndly, when making a bag, we need to know the size and shape of the bag, then can determine the shape and the size of the bag.

3.3rdly, we need to clearly get what kind of technology and workmanship should be adopted according to the material of the bag.

4.4thly, the bag structure is finished, finally we design the color combination, usually the decoration fabric is a little darker than main shell fabric.

In our factory, many kinds of bags every month produced, e.g. we use gun bag as an example to talk about it as follows.

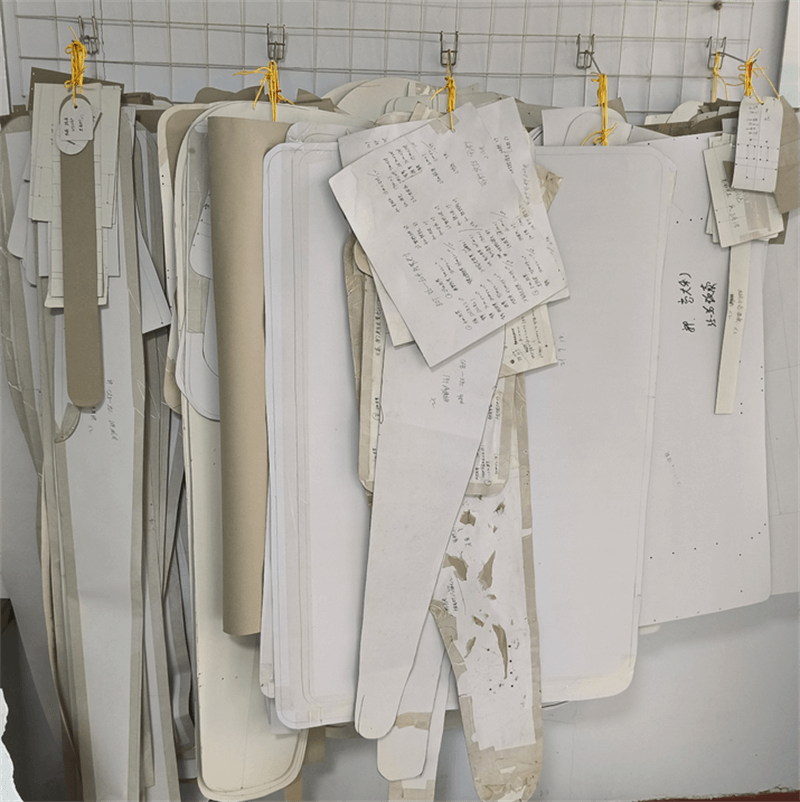

Each gun bag sample firstly needs to patterned, and then cutted as hanging in the sample showing room, then put rolled fabric to be flat on the cutting table, strictly cut each piece based on drawing line, after cutted, it needs to be fastened together soon.

Cutting Table is 18 meter length, pls have a look.

Below pls find well cutted pieces for shell / EPE, EVA, Sponge etc. / lining for bulk production.

Before sewing, our product QC team would check each style order’s shell, padding and lining based on sample cfmed bag, so that sew well for production.

Post time: Apr-13-2022